i-Control

Intelligent LPG Automation Control Panel

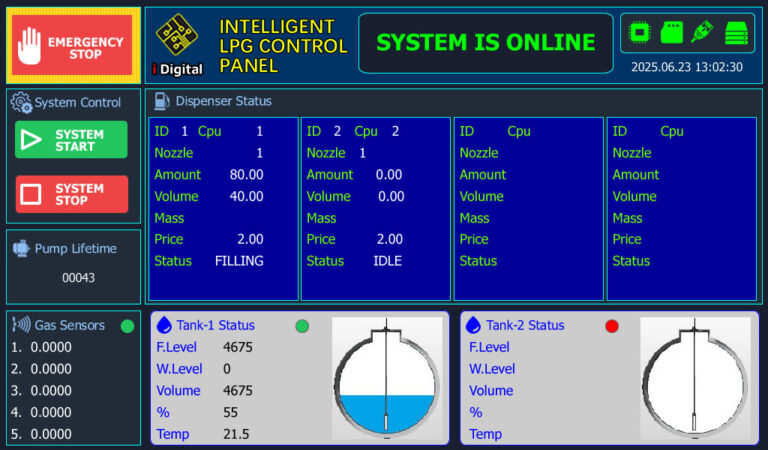

Total LPG Station Control Through one Intelligent Panel

i-Control LPG station control panel delivers an unparalleled solution for LPG station automation and safety. It features ATG, Forecourt Console and advanced LPG Control panel in one box.

Why Choose the i-Control LPG Station Control Panel?

- Centralized Live Dashboard: Instead of checking multiple devices, view the real-time status of your dispensers, tanks, and safety sensors on one clear, graphical screen.

- Dispenser Tracking: Instantly monitor LPG Dispenser transaction data including sales amount, volume, and price for each nozzle.

- Advanced Tank Management: Eliminate guesswork for wetstock, real-time data for each tank, including Fuel Level, Water Level, Volume, Fill Percentage, and Temperature.

- Uncompromising Safety: A prominent, one-touch EMERGENCY STOP button is always accessible. The system continuously monitors multiple gas sensors

- Proactive Maintenance: Track critical component usage with features like the Pump Lifetime counter, allowing you to schedule preventative maintenance and avoid unexpected downtime.

- Cloud Integration: All your data can be recorded to cloud server for remote monitoring and integration.

Main Fetures of LPG Control Panel

- Controls for up to 5 addressable gas sensors.

- Support for 4 addressable emergency stop buttons.

- Controls for 4 Rochester tank level monitors.

- Capability to control 4 tank level probes.

- Controls for 2 LPG dispensers, with the option to increase the number.

- Controls for 2 pumps, which can also be increased.

- Monitors fuel level by percentage or in liters.

- Ability to set upper and lower limits for filling.

- Includes gas sensor fault tracking.

- Features an energy protection and measurement monitoring system.

- Equipped with an LPG anti-gassing automatic control system that has day and night working options.

- Alarms and outputs can be adjusted according to customer requests.

- Provides an authorized tank filling system and leak filling notification.

- Cloud server integration.

LPG Control Panel Technical Specifications

Available with a 7″ or 4.9″ Touch LCD display.

Built on a custom-designed industrial embedded architecture.

Reads tank levels via LPG Level Probes or Rochester gauges.

Fully compliant with gas sensors available on the market.

Enables data communication with LPG tankers that arrive at the station.

Allows for direct communication and remote control to the Cloud via Ethernet or WIFI.

Supports remote version updates, backups, and fault tracking.

Protected against unauthorized interference at both the hardware and software levels.

Optional LPG Control Panel Features

Catalytic protection measurement and monitoring system.

Grounding measurement and monitoring system.

Anti-interference security system.

Connection for a smoke detector.

- RFID Reader.

- Printer.